The Essential Role of Automotive Sandpaper in Vehicle Restoration and Repair

Time:

2025-02-14 00:00

Source:

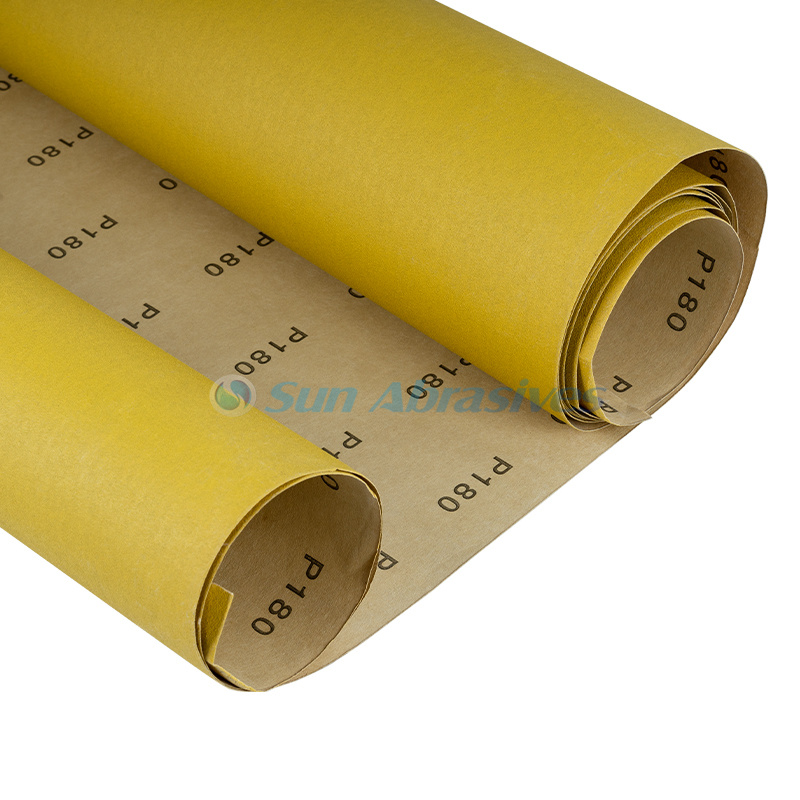

Automotive sandpaper is a specialized abrasive material critical for achieving flawless surfaces in vehicle repair and restoration. Unlike conventional sandpaper, it is engineered to handle the unique demands of automotive materials, such as metal, primer, and clear coat. Its primary function is to smooth imperfections, remove rust, and prepare surfaces for painting or refinishing. This tool’s efficiency lies in its abrasive grit composition, which varies based on the task’s requirements.

Automotive sandpaper is a specialized abrasive material critical for achieving flawless surfaces in vehicle repair and restoration. Unlike conventional sandpaper, it is engineered to handle the unique demands of automotive materials, such as metal, primer, and clear coat. Its primary function is to smooth imperfections, remove rust, and prepare surfaces for painting or refinishing. This tool’s efficiency lies in its abrasive grit composition, which varies based on the task’s requirements.

1. Key Types and Applications of Automotive Sandpaper

Automotive projects demand different grades of sandpaper. Coarse-grit variants (40-80 grit) excel at stripping paint or leveling deep scratches, while medium grits (120-220) refine surfaces before priming. Fine-grit options (400-1000+) are reserved for final polishing or blending paint edges. Wet-and-dry sandpaper, a popular subtype, allows for water-based sanding to reduce dust and prevent clogging. Professionals often pair these with dual-action sanders to balance speed and control.

2. The Science Behind Grit Selection and Surface Preparation

Choosing the correct grit grade is pivotal for optimal results. Aggressive grits risk gouging surfaces, whereas overly fine grits prolong labor without addressing deeper flaws. A structured approach involves starting with coarse grits for heavy material removal and progressively transitioning to finer grades. This method ensures a uniform substrate, which directly impacts coating adhesion and the longevity of automotive finishes.

3. Innovations in Automotive Sandpaper Technology

Modern advancements have elevated automotive sandpaper performance. Micro-abrasive coatings provide consistent wear resistance, while anti-static designs minimize debris buildup. Some products integrate non-woven fibers for contouring curved panels, a common challenge in car bodywork. Additionally, eco-friendly options with biodegradable backings are gaining traction, aligning with sustainability trends in the automotive industry.

4. Best Practices for Maximizing Efficiency and Safety

To optimize automotive sandpaper use, technicians should regularly clean abrasives with compressed air or specialized brushes. Pairing the right tool (e.g., orbital vs. belt sanders) with the correct grit prevents premature wear. Safety remains paramount: wearing respirators and goggles mitigates health risks from airborne particles. Proper storage in dry conditions also extends sandpaper shelf life.

5. Conclusion: Elevating Automotive Craftsmanship with Precision Tools

From rust removal to showroom-ready finishes, automotive sandpaper remains indispensable in achieving professional-grade results. By understanding grit dynamics, leveraging technological innovations, and adhering to best practices, technicians and hobbyists alike can transform challenging repairs into seamless restorations. Investing in quality abrasives ensures not only efficiency but also the durability of every automotive project.

Related News

undefined