The Indispensable Role of Emery Paper in Precision Manufacturing and Beyond

Time:

2025-04-16 00:00

Source:

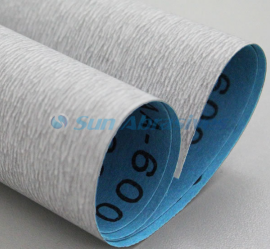

Emery paper, a type of abrasive material, has long been a staple in workshops, garages, and industrial settings. Composed of abrasive grains adhered to a paper backing, it is designed to smooth, shape, or polish surfaces through controlled abrasion. The effectiveness of emery paper lies in its versatility—it can be used on materials ranging from wood and metal to plastic and drywall. Its simplicity belies its critical role in achieving precise finishes, making it an essential tool for both professionals and DIY enthusiasts.

The utility of emery paper spans multiple sectors. In automotive manufacturing, it refines painted surfaces and removes imperfections during bodywork repair. Woodworkers rely on it to prepare timber for staining or sealing, while metal fabricators use it to deburr edges or blend welds. Even in construction, emery paper aids in smoothing drywall joints or preparing surfaces for painting. Its adaptability ensures it remains a go-to solution for tasks requiring surface finishing or material preparation.

Compared to other abrasives like sanding sponges or power tools, emery paper offers distinct benefits. Its flexible paper backing conforms to irregular shapes, making it ideal for detailed work. Additionally, it is cost-effective and disposable, reducing the need for complex cleanup or equipment maintenance. The ability to tear sheets into custom sizes further enhances its practicality, especially in tight or hard-to-reach areas. These traits solidify its status as a workhorse in grinding techniques and surface treatment.

From automotive refinishing to woodworking precision, emery paper continues to prove its worth as a reliable, adaptable abrasive. Its simplicity, cost-effectiveness, and versatility make it indispensable across industries.

Related News

undefined