Sanding Disc: A Modern and Efficient Sanding Option

Time:

2025-06-02 00:00

Source:

Sanding discs have emerged as a popular alternative to traditional sand paper in many applications, offering several advantages in terms of efficiency and convenience.

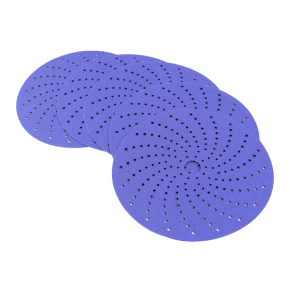

Usually glue is applied to the back of the sandpaper, or velcro cloth is attached, and the backing pad is cut into the corresponding size and hole shape, which is suitable for installation on pneumatic tools or electric tools, most commonly orbital sanders or disc grinders. This allows for a more even and efficient sanding process compared to using sand paper by hand.

One of the main benefits of using a sanding disc is the speed at which it can complete a sanding task. When attached to a power tool, the rotational motion of the disc can quickly remove material from the surface being sanded. For example, in a furniture-refinishing project, a sanding disc on an orbital sander can cover a large area of a wooden tabletop in a fraction of the time it would take to sand the same area by hand with sand paper.

Sanding discs also offer a more consistent finish. Because of the way they are attached to the power tool and the circular motion they create, they are less likely to leave uneven scratches or marks on the surface compared to manual sanding with sand paper. This is especially important in applications where a smooth and uniform finish is required, such as in the finishing of wooden cabinets or in the preparation of metal parts for plating.

Another advantage is the versatility of sanding discs. They come in a wide range of grits, from very coarse for rapid material removal to very fine for achieving a high-gloss finish. Different grits can be easily swapped out on the power tool depending on the stage of the sanding process. For instance, in automotive body repair, a coarse-grit sanding disc might be used initially to remove old paint or rust, followed by a series of finer-grit discs to prepare the surface for painting.

However, sanding discs also have some limitations. They require the use of a power tool, which means there is an additional cost involved if you don’t already own the appropriate equipment. Also, the circular shape of the disc may not be as effective for sanding in tight corners or on highly-contoured surfaces, where traditional sand paper may be more flexible. Nevertheless, sanding discs have revolutionized the sanding process in many industries and are a great choice for those looking for a more efficient and high-quality sanding solution.

Related News

undefined