Sanding Discs: A Comprehensive Overview of Types, Uses, and How to Maximize Performance

Time:

2025-09-16 00:00

Source:

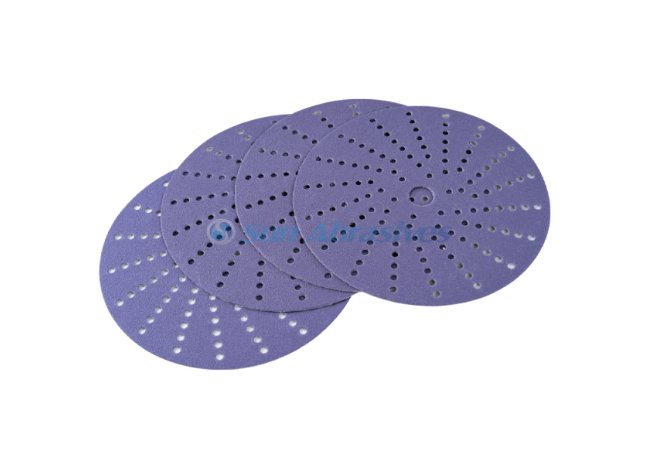

Sanding discs, a vital component of power sanding tools like angle grinders, random orbital sanders, and belt sanders, have revolutionized the way professionals and DIYers tackle surface preparation and finishing tasks. Unlike traditional sand paper sheets, sanding discs offer greater efficiency, uniform sanding, and compatibility with power tools—making them ideal for large-scale projects or hard-to-reach areas.

One of the most important factors to consider when choosing a sanding disc is the abrasive material, which determines its suitability for different surfaces. Aluminum oxide is the most versatile and widely used abrasive, making it perfect for sanding wood, metal, and plastic. It’s durable, cost-effective, and maintains its sharpness even during extended use—making it a top choice for general-purpose sanding. Silicon carbide, on the other hand, is harder and more aggressive, making it ideal for sanding hard materials like stone, glass, and ceramic. It’s also excellent for wet sanding applications, as it resists clogging and maintains its cutting power when exposed to water. For heavy-duty metalworking tasks, such as removing weld spatter or grinding down thick metal sheets, zirconia alumina is the go-to option—it’s extremely tough, self-sharpening, and can withstand high temperatures generated by power sanding.

The attachment system of a sanding disc determines how it connects to the power tool, and choosing the right system ensures safety and efficiency. Hook-and-loop (Velcro) attachments are the most popular, as they allow for quick and easy disc changes—no tools required. This is especially useful for projects that require switching between different grit sizes frequently, such as refinishing furniture. Pressure-sensitive adhesive (PSA) discs have a sticky backing that adheres directly to the sander’s pad, offering a secure hold that’s ideal for high-speed sanding tasks like smoothing drywall or sanding large wooden floors. For angle grinders and other heavy-duty tools, threaded or bolt-on discs are used—these attach via a screw or bolt, providing maximum stability for aggressive sanding or grinding.

Just like sand paper, grit size is a key factor in determining a sanding disc’s performance. Coarse grit discs (40–80 grit) are designed for rapid material removal, such as shaping wood, removing old paint from metal surfaces, or grinding down concrete. Medium grit discs (100–180 grit) are used for smoothing surfaces after coarse sanding, such as preparing wood for staining or removing scratches from metal. Fine grit discs (220–400 grit) are perfect for final finishing touches, like sanding between coats of paint or polishing metal to a smooth, matte finish. Ultra-fine grit discs (600–1200 grit) are reserved for delicate tasks, such as refining automotive paint jobs or sanding musical instrument bodies to a high-gloss finish.

To maximize the performance and lifespan of sanding discs, proper use and maintenance are essential. Always match the disc’s abrasive material and grit size to the surface you’re sanding—using the wrong disc can damage the material or result in a poor finish. For example, using a coarse aluminum oxide disc on softwood can cause splintering, while using a silicon carbide disc on metal may wear out quickly. Additionally, avoid applying excessive pressure to the sander—let the tool’s weight do the work, as too much pressure can cause the disc to clog or overheat, reducing its effectiveness. After use, clean the disc with a disc cleaner or a stiff brush to remove dust and debris, which can clog the abrasive particles and reduce cutting power.

Related News

undefined