The Versatile Abrasive Paper Manufacturing Process and Tips for Using

Time:

2025-05-14 00:00

Source:

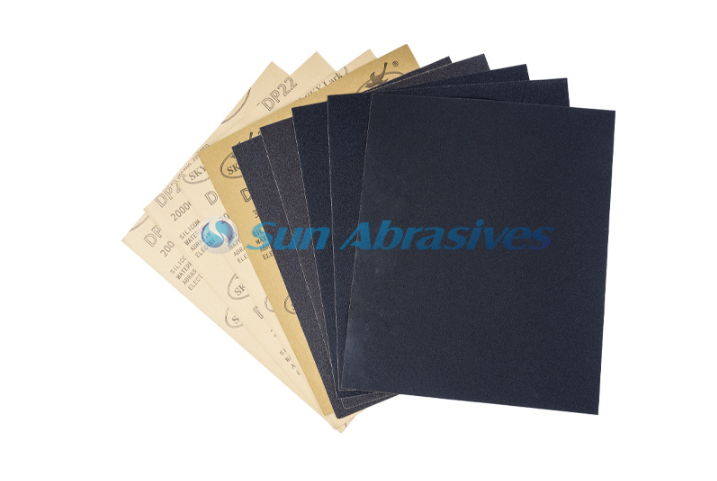

The manufacturing process of abrasive paper is a complex one. First, the backing material is prepared. For paper-backed abrasive paper, a high-quality paper is selected. Then, the adhesive is applied to the backing. The adhesive plays a vital role in holding the abrasive grains firmly. Next, the abrasive grains are evenly spread over the adhesive-coated backing. After the sandpaper is dried, a second coat of resin is applied and it goes through a second drying and curing process to ensure the particles are firmly attached. Quality control is an important step in the manufacturing process. Manufacturers need to check the coating uniformity and the adhesion strength of the abrasive grains to ensure the performance of the abrasive paper.

Abrasive paper has a wide range of applications. In the woodworking industry, it is used for sanding and smoothing wooden surfaces. Woodworkers use different grits of abrasive paper to achieve different levels of smoothness. For example, a coarse-grit abrasive paper is used for initial shaping and removing large amounts of material, while a fine-grit abrasive paper is used for final finishing. In the automotive industry, abrasive paper is used for preparing surfaces before painting. It helps to remove rust, old paint, and other imperfections. In the metalworking industry, it is used for grinding and polishing metal parts. Abrasive paper can also be used in the DIY (do-it-yourself) projects at home. For instance, for refinishing furniture or fixing small scratches on various objects.

When using abrasive paper, there are several tips to keep in mind. First, always choose the right grit for the job. A coarse grit is good for heavy material removal, while a fine grit is for finishing. Second, use proper pressure. Applying too much pressure can cause uneven sanding and may damage the surface. Third, change the abrasive paper when it becomes dull. A dull abrasive paper will not cut effectively and may leave scratches. Fourth, when sanding curved surfaces, it is better to use a flexible abrasive paper or wrap the abrasive paper around a suitable object to conform to the shape of the surface.

In conclusion, abrasive paper is a versatile and essential material. Its wide range of applications in different industries, from woodworking to automotive and metalworking, makes it an indispensable tool. Understanding its manufacturing process, applications, and proper use can help users get the best results. Whether it is for professional use in industrial settings or for DIY enthusiasts at home, abrasive paper will continue to play an important role in achieving smooth, polished, and well-prepared surfaces.

Related News

undefined