Ultimate Guide to Film Sanding Discs: Precision and Durability for Industrial and DIY Applications

Time:

2025-06-11 00:00

Source:

In the world of surface finishing, film sanding discs have emerged as a game-changing solution for professionals and hobbyists alike. These advanced abrasive tools combine durability, flexibility, and precision to deliver consistent results across a wide range of materials and applications.

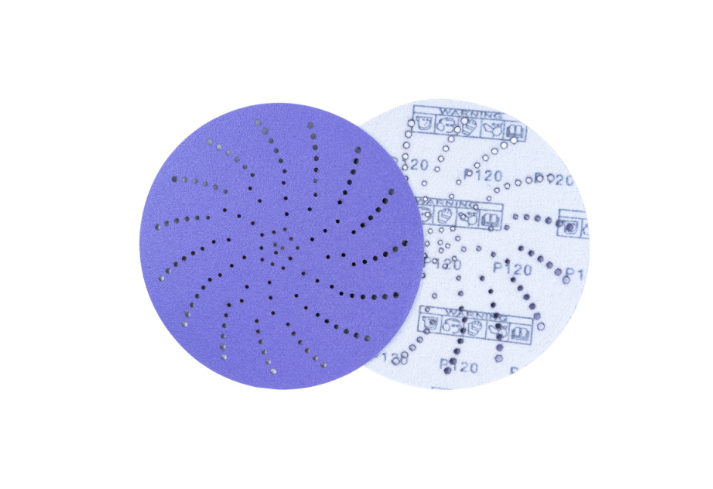

Film sanding discs are engineered with a polyester film backing instead of traditional paper or cloth. This backing, often made from PET (polyethylene terephthalate), offers exceptional tear resistance and flexibility, allowing the disc to conform to curved or irregular surfaces without compromising performance. The abrasive grains—typically aluminum oxide, silicon carbide, or ceramic—are bonded to the film using resin technology, ensuring uniform distribution and long-lasting cutting power.

Key design elements include:

- Anti-loading coatings: These prevent debris from clogging the disc, maintaining efficiency during prolonged use.

- Waterproof properties: Film Sanding discs are generally dry sanding, If there is a need for waterproofing, a small amount of water can be added for sanding after adding waterproof materials during the production process.

- Hook-and-loop (VELCRO) or PSA (pressure-sensitive adhesive) backing: Both allow quick disc change

Applications Across Industries

Film sanding discs are versatile tools with applications spanning multiple sectors:

1. Automotive Refinishing

In automotive workshops, film discs are indispensable for:

- Surface preparation: Removing old paint, rust, and imperfections before repainting. Coarse grits (P80–P180) tackle heavy material removal, while fine grits (P400–P1000) refine surfaces for a seamless finish.

- Feather edging: Blending paint repairs by creating smooth transitions between old and new coatings.

- Clear coat sanding: Achieving a mirror-like finish on vehicle surfaces using ultra-fine grits (P1200–P2000).

2. Woodworking and Furniture Making

Woodworkers rely on film discs for:

- Sanding between coats: Smoothing surfaces between layers of varnish or lacquer to enhance adhesion.

- Edge sanding: Preventing tear-out on delicate wooden edges with flexible film backing.

- Fine finishing: Achieving uniform scratch patterns on hardwoods and veneers, critical for staining and painting.

3. Metal Fabrication

Metalworking applications include:

- Deburring: Removing sharp edges from machined parts.

- Surface preparation: Preparing metal surfaces for powder coating or plating using medium to coarse grits (P60–P220).

- Polishing: Achieving high-gloss finishes on stainless steel or aluminum with fine grits (P800–P2000).

4. Plastics and Composites

Film discs excel in:

- Mold release preparation: Smoothing plastic surfaces for bonding or painting.

- Composite finishing: Trimming and refining carbon fiber or fiberglass components in aerospace and marine industries.

Advantages Over Traditional Sandpaper

Film sanding discs outperform paper-backed alternatives in several critical areas:

- Durability: The polyester film backing resists tearing and edge wear, lasting 2–3 times longer than paper discs.

- Consistent Finish: Uniform grain distribution ensures even abrasion, reducing the risk of scratches or gouges.

- Clog Resistance: Anti-loading coatings keep the disc clean, maintaining cutting efficiency.

- Flexibility: Film discs conform to curved surfaces, ideal for complex geometries.

Choosing the Right Film Sanding Disc

Selecting the optimal disc involves considering:

- Grit Size:

- Coarse (P40–P120): For heavy material removal.

- Medium (P150–P320): For surface preparation.

- Fine (P400–P2000): For finishing and polishing.

- Abrasive Material:

- Aluminum oxide: Good wear resistance, long service life

- Silicon carbide: Good sharpness, fast grinding speed

- Ceramic sand: High hardness, high wear resistance, good self-sharpening

- Backing Type:

- Velcro and PSA are only used with corresponding sanding discs. If the sanding pad is hook and loop, use velcro. If the pad is flat, use PSA.

- Disc Size and Hole Pattern: Match the disc diameter (e.g., 5", 6") to your sander and use hole patterns for dust extraction

Related News

undefined